Delrin® and Sustakon® are both semi-crystalline thermoplastics that are used in many industries today. In the reciprocating plunger pump world, these thermoplastics are used in the disc or valve seat of the plate valve, spherical valve, or Durabla® valve and can play a key role in the reliability, durability and longevity of these valves. Since the valves are exposed to a variety of often harsh environments, it’s important to understand which thermoplastic is better suited for each application. Let’s take a closer look at them individually, and then we’ll do the apple to apple test.

Delrin®

Introduced commercially in 1960, Delrin® acetal resins are semi-crystalline, thermoplastic polymers made by the polymerization of formaldehyde. Due to its use in such diverse industries including automotive, appliance, construction, hardware, electronics, and components, Delrin® has many other industry tradenames such as Acetal, Acetron , PolyOxyMethylene (POM), and Unital, to name a few.

While there are many compositions available, the highest viscosity composition commonly used in pump valve discs and seats features:

- high mechanical strength and rigidity

- excellent fatigue endurance

- high resistance to repeated impact

- resistance to moisture, gasoline, lubricants, solvents, and many other neutral chemicals

- most of these properties are maintained in operating temperatures up to 160°F

Sustakon®

Introduced on June 13, 2014, Sustakon® is a semi-crystalline thermoplastic based on Ethylen, Propylen, and carbon monoxide. Typical areas of application include seals, aircraft construction, ship building, offshore, and mechanical engineering.

Also known as Polyketone or PK, it has the following special properties:

- very good resilience

- low moisture absorption

- high impact strength

- very high abrasion resistance

- long time use temperature up to 248°F

These characteristics allow components to be used in areas with high mechanical, tribological, and chemical requirements at the same time.

Comparison

Both Delrin® and Sustakon® work well with temperatures up to 160°F, however, if the temperature of the liquid is higher, the recommended materials for the valve disc or seat are either Sustakon® (up to 248°F) or metal.

Characteristics such as high strength, moisture resistance, and good stability are common factors for both thermoplastics. Two areas of difference – temperature and chemical resistance – require a closer look to determine the better choice for your valve disc or seat.

The following table shows the chemical resistance for Delrin® (POM) and Sustakon® (PK):

| GROUP | Examples | POM | PK |

| Hydrocarbons (straight) | methane, ethane, octane, propane | yes | yes |

| Hydrocarbons (halogenated) | chlorofluorocarbons (CFCs) | yes | yes |

| Ketone | propanone, phenylethanone | yes | yes |

| Ester/Ether | methyl butanoate, methoxyethane | yes | yes |

| Aldehyde | methanal, hydroxybutanal | yes | yes |

| Water | yes | yes | |

| Acidic (weak) | methanoic acid, ethanoic acid | no | yes |

| Acidic (strong) | hydrochloric acid, sulfuric acid, nitric acid | no | no |

| Alkalis (weak) | ammonia | yes | yes |

| Alkalis (strong) | sodium hydroxide, calcium hydroxide | yes | no |

| Salt Solutions | sodium acetate, ammonium chloride | no | yes |

Conclusion

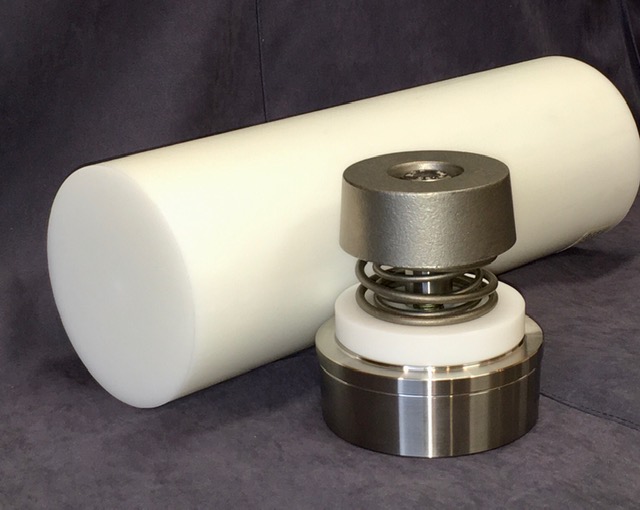

Incorporating Delrin® or Sustakon® in your disc or valve seat selection is only one of the decisions you’ll make when determining how to get the most out of your valve. In order to achieve the reliability, longevity, and durability desired, selecting the right pump valve is also crucial.

Triangle Pump Components Inc. has been the leader in quality reciprocating plunger pump components for over a century. To learn more about our valves, download our Valve Comparison Chart or for more information on any of our products, contact us today.