PlenaFlow® Plate Valve Installation

Proper plate valve installation is crucial for maximizing operating efficiency and extending the service life of your system. Like all Triangle Pump Component valves, the PlenaFlow® plate valve is designed to be long-lasting when accurately installed.

To ensure the safe, proper installation of your PlenaFlow® plate valve, follow these steps:

- Pump ports must be clean and free from foreign matter, rust, or corrosion.

- Clean and dry the tapered part of the valve seat.

- Place the valve seat in the pump port and press down with the palm of the hand making sure the seat is aligned straight and level in the port.

- Place a short wood block on top of the seat. The wood block should be of sufficient size to cover the entire seating diameter.

- Tap lightly with a hammer or mallet. Under no circumstances should you use a sledge or heavy blow of any kind directly on the valve seat. A properly fitting valve seat will be “home” with light tapping. Pump action will seat the unit precisely and firmly by equalized liquid pressure.

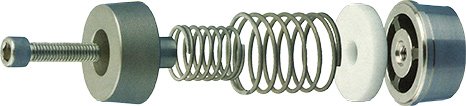

- Install valve, springs, retainer, and fastener. For assembly order see Typical Plate Valve Assembly exploded diagram above.

- Rotate the pump crankshaft by hand to make sure plunger and packing are in proper alignment.

Caution: It is possible to freeze a valve closed by:

- Over tightening the fastener. This can possibly expand the retainer stem.

- Positioning the retainer stem on top of the valve plate while tightening the fastener.

For more information about our PlenaFlow® plate valves,

Experiencing pumping issues and need help troubleshooting?